5 Technical Tips, Price, and the Best Brands of Geomembrane Welding Machines

“Shahriyar Baspar Arian” Company — Manufacturer and Supplier of “Arian Weld” Machines

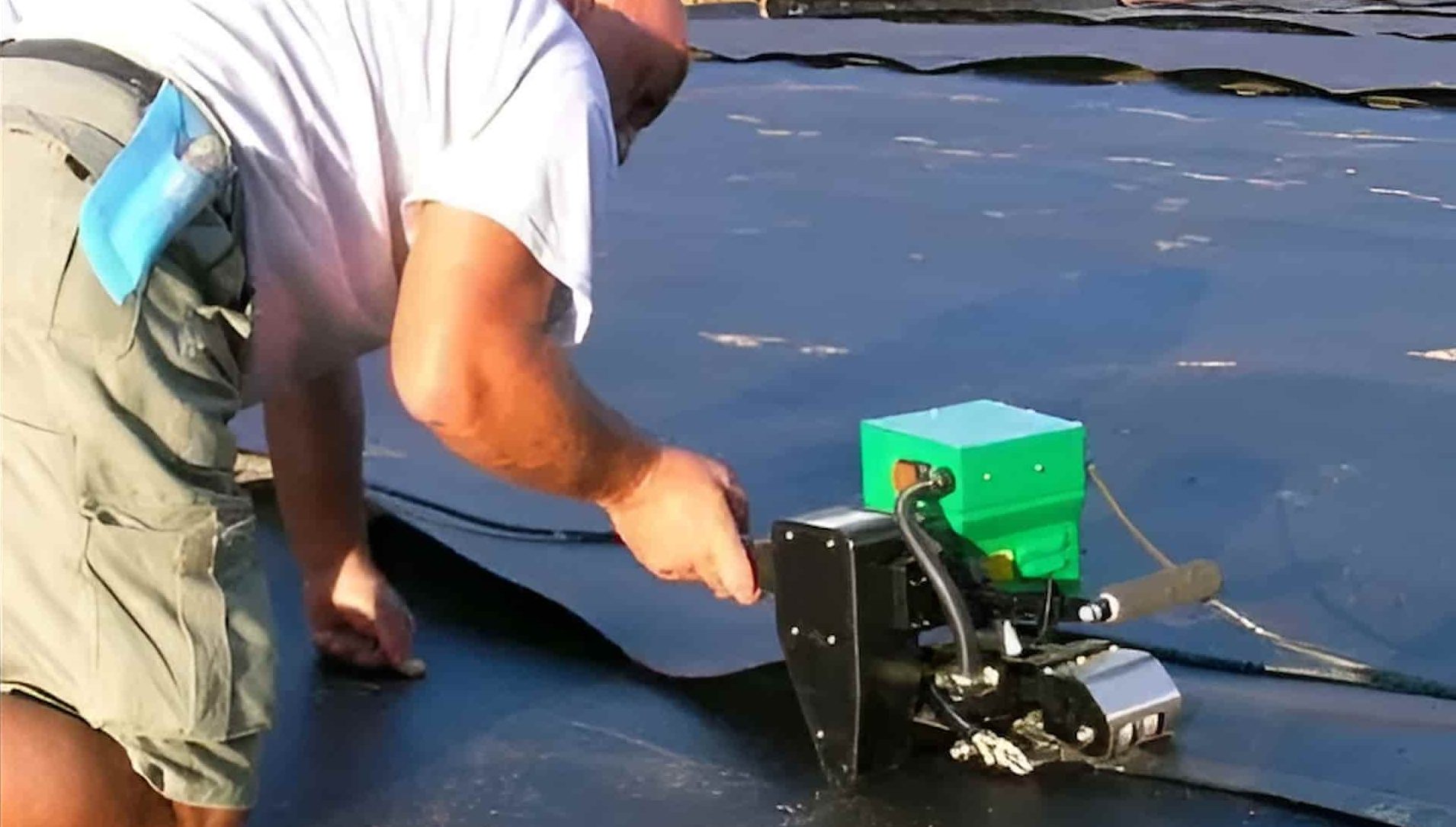

In drainage projects, ponds, landfills, and geomembrane lining systems, the quality of the weld between two geomembrane sheets determines the durability and performance of the entire system. Choosing the right welding machine not only increases execution speed but also reduces installation errors and future repair costs.

Below, five key technical points to consider when selecting and using a geomembrane welding machine are explained. Then, typical market price ranges and several reputable brands are introduced, followed by a review of “Arian Weld” and the competitive advantages of its Iranian manufacturer, Shahriyar Baspar Arian.

1 — Technical Tip: Welding Technology Type and Material Compatibility

Geomembrane welding machines generally operate based on three main technologies: hot air (Hot-air/Hot-wedge), hot wedge, and extrusion welding (hot-melt).

For high-density polyethylene (HDPE), hot-wedge or extrusion welders usually provide safer and deeper thermal penetration.

PVC, TPO, and LDPE membranes can be welded with hot air or roller machines that have precise temperature and pressure control.

The selected welding technology must match the membrane type and thickness; incorrect selection may cause weak welds or thermal damage.

2 — Technical Tip: Controlling Parameters — Temperature, Pressure, and Travel Speed

Three main parameters define the weld quality: temperature, pressure (force or roller weight), and the travel speed of the machine.

- Accurate, stable, and adjustable temperature is essential for different materials and thicknesses — precise sensors and digital displays are a must.

- Uniform pressure across the welding area (via adjustable rollers) ensures proper fusion and prevents bubbles or voids.

- The travel speed must match the temperature; too high or too low speed can both reduce weld quality.

Professional-grade machines allow continuous adjustment of these three parameters and the ability to save welding profiles — crucial for large-scale projects.

3 — Technical Tip: Mechanical Design and Ergonomics for Field Work

In field projects, weight, body durability, ease of replacing consumables (nozzles, heating elements, rollers), and portability are key factors. Machines with quick-replacement mechanisms and easily available spare parts minimize downtime. Protective cases, safety thermostats, and accessible fuses are also vital for work in remote sites.

4 — Technical Tip: Post-Weld Testing and Quality Control

After welding, both non-destructive and destructive tests must be performed — including manual peel/tensile tests, air pressure tests using balloons (or temporary pond leak tests), and for sensitive projects, ultrasonic or pressure gauge inspections at the seam. Having a manual of standards and testing procedures for operators ensures reproducibility and traceability of results.

5 — Technical Tip: After-Sales Service, Spare Parts, and Operator Training

Although the machine may look simple, weld quality heavily depends on operator skill. Providing an educational package with the machine (video tutorials, Persian manuals, on-site or online training) and ensuring spare part availability (heating elements, microswitches, nozzles, rollers) adds great value.

This is one of the major advantages of local manufacturers like Shahriyar Baspar Arian, who offer faster service and native-language support — especially valuable for contractors and local operators.

Market Prices and Typical Ranges

Geomembrane welding machine prices vary widely depending on type (handheld to full automatic), country of origin, and power or control features:

- Handheld and semi-professional machines (such as hot-air welders) are typically priced from a few hundred to around one thousand USD (consumer and general-purpose brands).

- Medium industrial hot-wedge welders are usually priced between USD 1,500 and 5,000 (models from 1200 to 3000 watts with semi-automatic capability).

- Automatic and large-width industrial machines (such as TAPEMAT or GEOSTAR) designed for major projects can range from several thousand up to over 20,000 USD for fully automated, high-performance systems.

Note: In Iran, import duties, customs, and after-sales support significantly affect final pricing. Therefore, domestically produced or locally assembled machines (such as “Arian Weld” by Shahriyar Baspar Arian) can reduce the total cost of ownership (TCO).

Top Brands and Product Categories

In the global market, several reputable brands stand out in product range and technical reliability:

Leister — One of the most recognized European brands for plastic and membrane welding machines; offering everything from handheld tools to automatic systems, known for durability and precision.

Other specialized European/American manufacturers produce high-end industrial and automatic machines — often chosen for critical engineering projects.

Asian and Chinese manufacturers offer a wide variety of models at lower prices, suitable for limited-budget users or less demanding projects, though spare part and service availability should be carefully checked.

The Position of “Arian Weld” (Shahriyar Baspar Arian) — A Smart Choice for Iranian Contractors

Since Shahriyar Baspar Arian manufactures “Arian Weld” machines locally, several competitive advantages are evident:

- Designed for local field conditions — optimized for the types of geomembranes commonly used in Iran and the region.

- Faster access to parts and services — reduces project downtime compared to imported units with long delivery times.

- Competitive pricing — by removing import and customs costs, overall value increases significantly.

- Persian-language training and support — educational materials, on-site consulting, and guidance aligned with practical standards reduce operator error.

It is recommended to request a demo, technical documentation, spare parts list, and operator training plan before purchase. Warranty and guarantee terms should also be clearly defined.

Summary and Final Recommendations

For selecting the right geomembrane welding machine:

- Determine the membrane type, thickness, and project scale first.

- Choose the appropriate technology (hot air / hot wedge / extrusion) accordingly.

- Ensure the device offers precise control over temperature, pressure, and speed — and that spare parts are accessible.

- Compare the total cost of ownership (purchase + parts + training + maintenance), not just the initial price.

For quick service, local support, and updated geomembrane welding machine prices, choosing a domestic manufacturer or representative such as Shahriyar Baspar Arian (Arian Weld) can be a wise and cost-effective decision.