How to Choose the Best Geomembrane Welding Machine?

Shahriar Bespar Aryan — the largest and first manufacturer of geomembrane welding machines under the brand Arian Weld in Iran and the Middle East.

Choosing the right welding machine for geomembrane installation can mean the difference between a durable, decades-long seal and a costly leak. In this article, we review the key technical, operational, and economic factors to help engineers, contractors, and buyers make informed decisions.

For installation and project execution, contact us today — with a 10-year warranty on products and services, you’ll achieve the best performance.

1) Know Your Material First

The choice of machine depends on the type of geomembrane (HDPE, LLDPE, PVC, EPDM, etc.). Some materials are better suited for the hot wedge method, while others require extrusion welding.

Before purchasing, determine which material types and thicknesses you’ll be working with most often, and select a machine designed and calibrated for them.

(Reference: Industrial standards specify compatible materials and welding methods.)

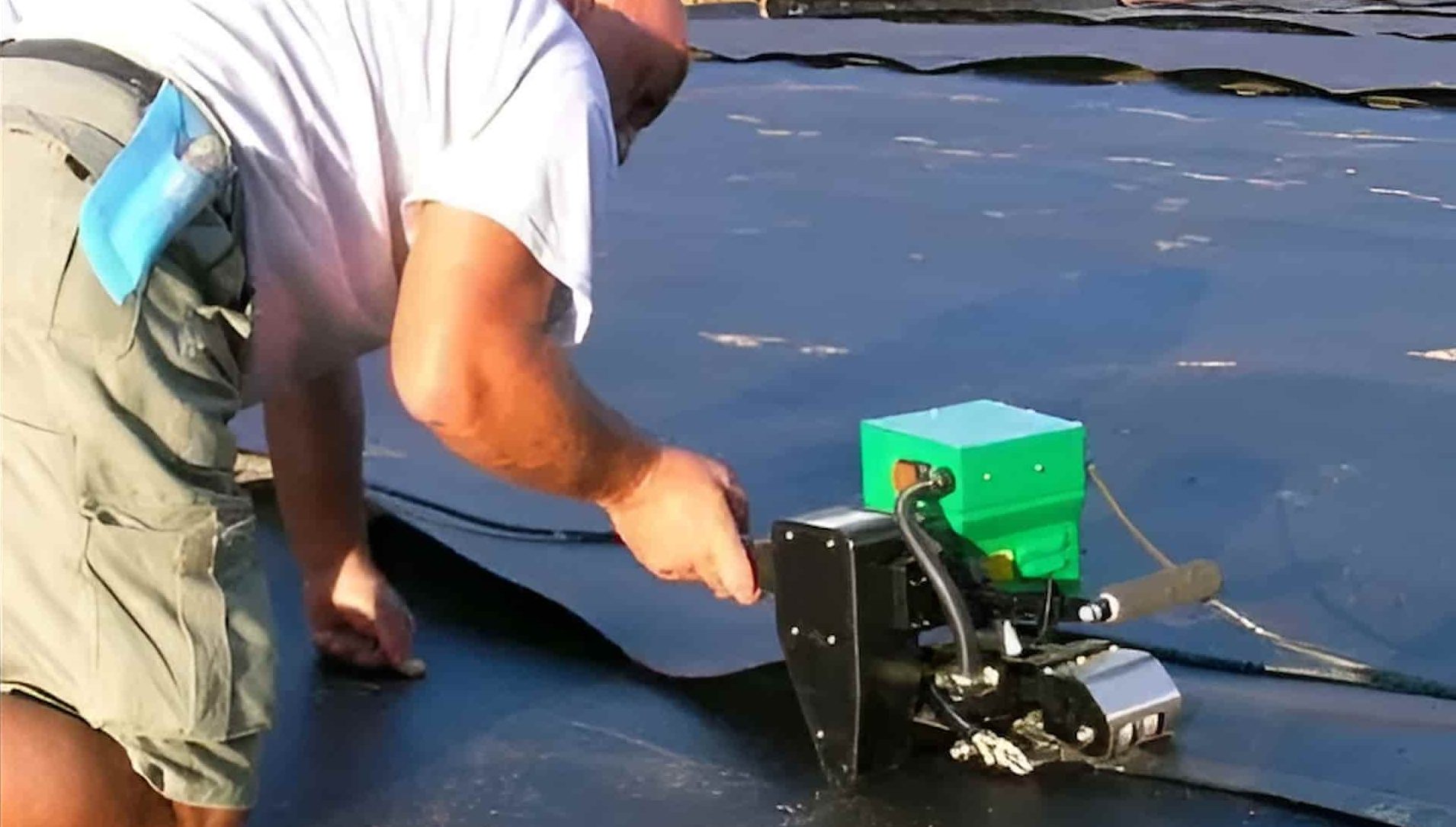

2) Welding Method — Hot Wedge, Hot Air, or Extrusion?

There are three common welding methods:

Hot Wedge (electrically heated wedge): Produces dual seams with an air channel in between; ideal for large projects with high-speed welding. According to modern standards, parameters such as temperature, speed, and pressure must be controlled and recorded.

Hot Air: Suitable for thinner materials and detailed joints; offers flexible temperature control.

Extrusion Fillet Welding: Used for strong, durable seams where molten filler is required, typically with thick polyethylene liners.

Your choice depends on the project type (landfill, water reservoir, fish pond), the availability of skilled operators, and required quality testing.

3) Data Logging and Control — A Must, Not a Luxury

Modern standards emphasize recording welding parameters (temperature, speed, pressure) to ensure every seam is traceable and comparable.

Prioritize machines with built-in data loggers and export options (compatible with QA/QC software). This feature enhances quality assurance and simplifies accountability in case of issues.

4) Temperature Precision and Parameter Repeatability

Accurate temperature control and continuous speed adjustment are critical, especially for temperature-sensitive materials like PVC or modified polymers. The machine should allow easy calibration and have a clear, reliable display.

5) Seam Width, Power Output, and Real Field Speed

The required seam width and power (thermal and electrical) must match your project needs.

For large-scale installations, durability and consistent performance matter more than a slightly lower purchase price.

Also, ensure the machine’s power requirements match your site’s power source or that it can operate with a generator.

6) Field Durability and Ease of Use

Environmental conditions (temperature, wind, dust, slope) directly affect welding performance.

Choose machines with rugged construction, dust protection, and flexible cables for sloped or uneven sites.

Simple controls and fault indicators are also essential for operator safety and efficiency.

7) Safety and Standards

Your welding machine must comply with international standards and test procedures for geomembrane seams.

Key references include GRI standards (such as GM13 for HDPE) and ASTM welding and testing standards.

Selecting a machine capable of field testing and data logging in compliance with ASTM standards minimizes project risk.

8) After-Sales Service, Spare Parts, and Operator Training

The service life and quality of welded seams depend heavily on operator skill and machine maintenance.

Choose a supplier that:

- Provides hands-on operator training,

- Offers fast spare-part replacement and warranty,

- Performs regular service and calibration.

In Iran and the Middle East, local technical support is a major advantage.

Shahriar Bespar Aryan, as the first and largest manufacturer of Arian Weld machines, provides a strong regional service network and deep local experience — minimizing project risk and ensuring consistent performance.

9) Life-Cycle Cost — Not Just the Purchase Price

A low purchase price can be deceptive; total cost includes downtime, defect rate, training, and spare parts.

A higher-quality machine with consistent seam strength and minimal test failures will save far more over its lifetime.

10) Quick Decision Checklist

- Type and thickness of geomembrane

- Suitable welding method

- Accuracy and data logging capability

- Compliance with local and international standards

- Training and after-sales support

- Power compatibility and real output

- Availability of spare parts and repair service

Conclusion: Why “Arian Weld” Is a Strong Choice

For regional buyers, a supplier that manufactures, trains, and supports locally delivers far greater value than a simple importer.

Shahriar Bespar Aryan, as the first and largest manufacturer of geomembrane welding machines in the region, designs its equipment to meet international welding standards with full data recording capability — ensuring reduced operational risk, easier quality control, and quick access to service and spare parts.