5 Key Features of a Professional Geomembrane Welding Machine Every Contractor Should Know

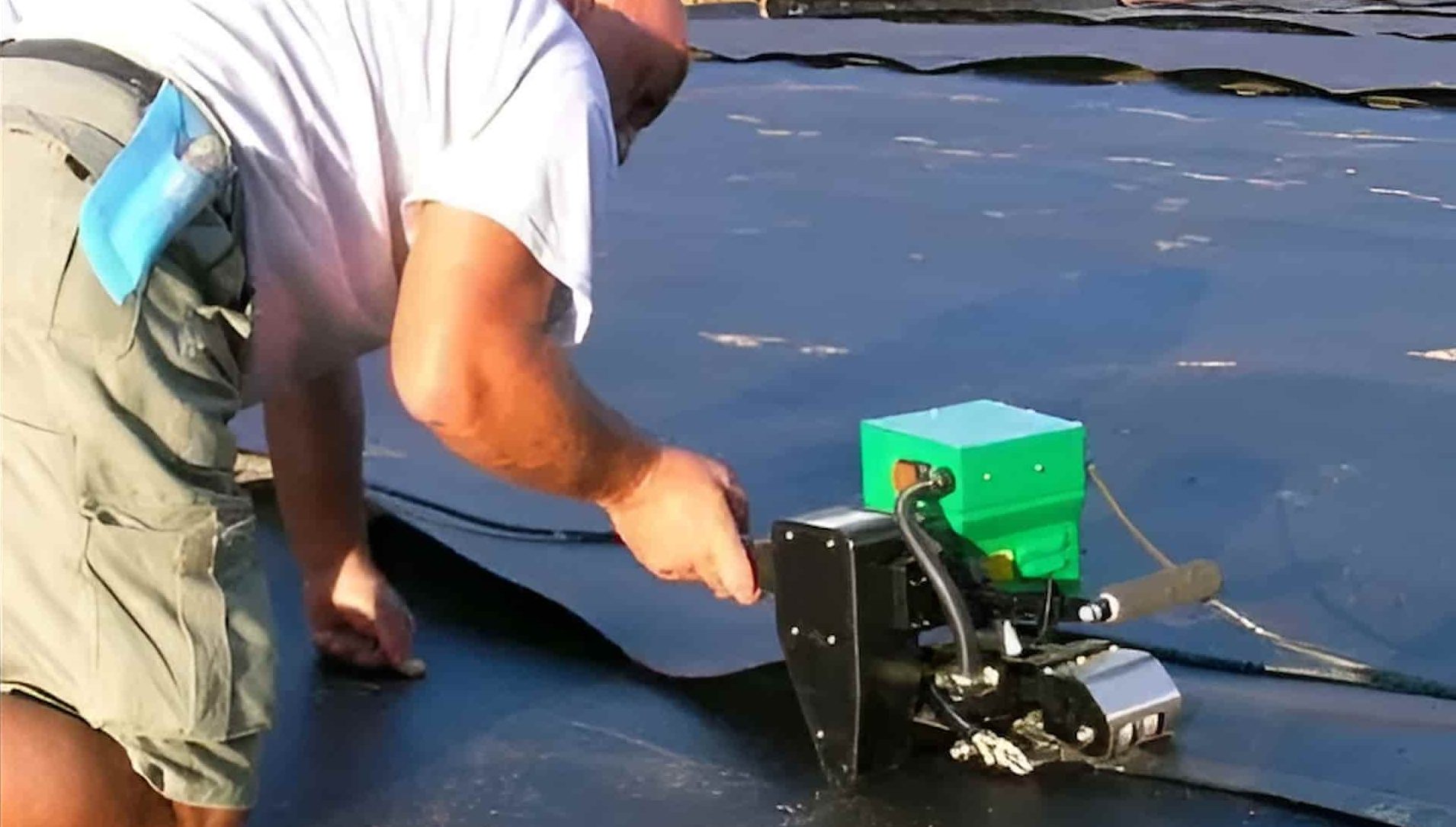

In civil engineering projects such as lining of waste ponds, small dams, water and wastewater facilities, or green roof coverings, the quality of geomembrane welding determines the durability and watertightness of the structure. Choosing the right welding machine not only improves efficiency and installation speed but also significantly reduces the risk of leakage and future damage.

In this article, we explain five key features that every professional contractor should know when purchasing or evaluating a geomembrane welding machine — considering that Shahriar Bespar Arian is the manufacturer and supplier of Arian Weld welding machines, which can be a practical option for Iranian contractors.

1. Precise Temperature Control and Thermal Stability

Geomembrane welding is based on melting and bonding layers through controlled heat; therefore, precise temperature control is the most important indicator of weld quality.

- Temperature adjustment accuracy: The machine must be able to adjust the temperature with an accuracy of at least ±1°C to be suitable for various materials (HDPE, LLDPE, PVC, etc.).

- Thermal stability under real working conditions: In hot or cold environments and during long-term operation, temperature fluctuations should not affect weld quality. High-quality sensors and control algorithms (such as PID) ensure stability.

- Temperature display and logging: The ability to monitor temperature in real time and record data logs for quality review is a major operational advantage.

Practical tip: When evaluating a machine, ask the supplier to demonstrate the temperature range and precision, and request a sample weld if possible.

2. Uniform Heating and Heater/Extruder Design

One of the most common causes of seam defects is uneven heating—some areas of the liner melt properly while others are under- or over-heated.

- Heater or extruder structure: The quality of heating elements, their arrangement, and air/heat flow path must ensure uniform heat distribution.

- No heat concentration: Good design prevents “hot spots” that can locally burn the liner.

- Adaptability to rolls and edges: The heating system should be adjustable for different liner thicknesses and overlap conditions.

Recommendation: Machines that provide microscopic or tensile tests of the weld seam demonstrate superior heating performance and machine capability.

3. Adjustable Speed, Pressure Force, and Welding Head Mechanics

A strong weld results from the right combination of temperature and pressure. Even with correct heat, improper pressure or speed can lead to weak bonding.

- Controllable welding speed: The travel speed must be adjustable for different liner types and thicknesses.

- Roller pressure adjustment: Excessive pressure may thin the weld seam, while insufficient pressure results in poor bonding. The machine should allow pressure adjustment and display.

- Mechanical design of the welding head: The head must have high structural precision to evenly distribute pressure and prevent slippage or deviation during movement.

Contractors’ experience shows that the ability to adjust multiple parameters independently (temperature, speed, pressure) provides high adaptability on-site.

4. Ergonomics, Safety, and Portability — Designed for Real Job Sites

Outdoor job site conditions are often harsh and variable; thus, user-friendly and safe design is essential.

- Weight and portability: Machines that are detachable or equipped with wheels are better suited for sites with limited access.

- Safety guards and shut-off systems: Thermal shields, automatic cut-offs in case of unstable power or excessive heat, and emergency stop buttons are essential.

- Ease of setup and field adjustment: Contractors often have limited training time; the machine should have an intuitive interface, clear manual, and straightforward settings.

- Spare parts quality and availability: For long-term projects, having access to spare parts (heating elements, rollers, bushings) and fast service is critical.

Business note: Companies like Shahriar Bespar Arian, being both manufacturer and supplier, have the advantage of providing local spare parts and after-sales service — a key strength for contractors in Iran.

5. Quality Control Capabilities, Data Logging, and Compliance with Standards

To ensure and verify weld quality in contracts and audits, the machine should include logging and reporting features.

- Parameter recording: Recording temperature, speed, and pressure for every meter of weld allows contractors to provide quality reports to clients.

- On-site testing: Some machines facilitate non-destructive tests or sample tensile testing for seam quality assurance.

- Compliance with standards: Ensuring that the machine and welding process comply with international and national geomembrane welding standards is essential for formal projects.

- Upgradable and software-based controls: Machines with software-controlled profiles enable saving and recalling weld settings, improving accuracy and traceability.

Tip: Ask the supplier to show certificates or sample reports generated by the machine.

Practical Tips for Contractors When Choosing a Machine

- Define your project needs: The liner thickness, material type, project size, and environmental conditions determine the required machine specifications.

- Request a field test: Always ask for a sample weld and quality test before purchasing.

- Check local support: Spare parts delivery time and after-sales service response in Iran are critical — local manufacturers or representatives have a clear advantage.

- Assess total cost of ownership: The initial price is only part of the cost; include repairs, consumables, and training in your calculation.

- Train your crew: Even the best machine cannot perform well without a trained operator — reliable suppliers usually offer on-site training with the machine.

Conclusion

Choosing the right geomembrane welding machine for contractors means balancing technical precision (temperature, uniform heating, pressure, and speed), quality control capabilities, and after-sales service support.

The Arian Weld machines, manufactured and supplied by Shahriar Bespar Arian, are designed for the local market with a focus on reliability and fast support — making them an excellent choice for contractors seeking dependable equipment.

For detailed technical information, field testing, and consultation on the most suitable model for your project, please contact the Shahriar Bespar Arian office.