Introduction to Arian Weld Machines, Extruders, and Industrial Hot Air Guns at Shahriar Baspar Arian Company

In civil, environmental, and agricultural projects where geomembrane sheets are used for waterproofing, the quality of the weld joints plays a decisive role in the overall success of the project.

A weak weld can lead to leakage, erosion, and serious damage, while selecting the right welding machine and applying proper techniques can ensure structural durability for decades.

In this article, **Shahriar Baspar Arian Co.** and **Khanjani Polymer Industries**, two specialized companies active in the field of geomembrane production and installation, present a comprehensive guide for selecting the appropriate welding machines.

The guide focuses on three commonly used types of equipment:

- Dual Wedge Welding Machine (such as Arian Weld)

- Extrusion Welding Machine

- Industrial Hot Air Gun

🔹 Why Is Choosing the Right Geomembrane Welding Machine Important?

Geomembrane sheets are made of high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE).

To properly join two sheets, the polyethylene must be evenly melted and fused at the seam.

Each type of welding machine performs differently depending on the project type, sheet thickness, and environmental conditions.

Using the wrong equipment can lead to:

- Reduced weld strength

- Water or gas leakage through seams

- Increased rework and wasted time

- Reduced service life of the geomembrane

Therefore, understanding the technical features and applications of each welding system is essential.

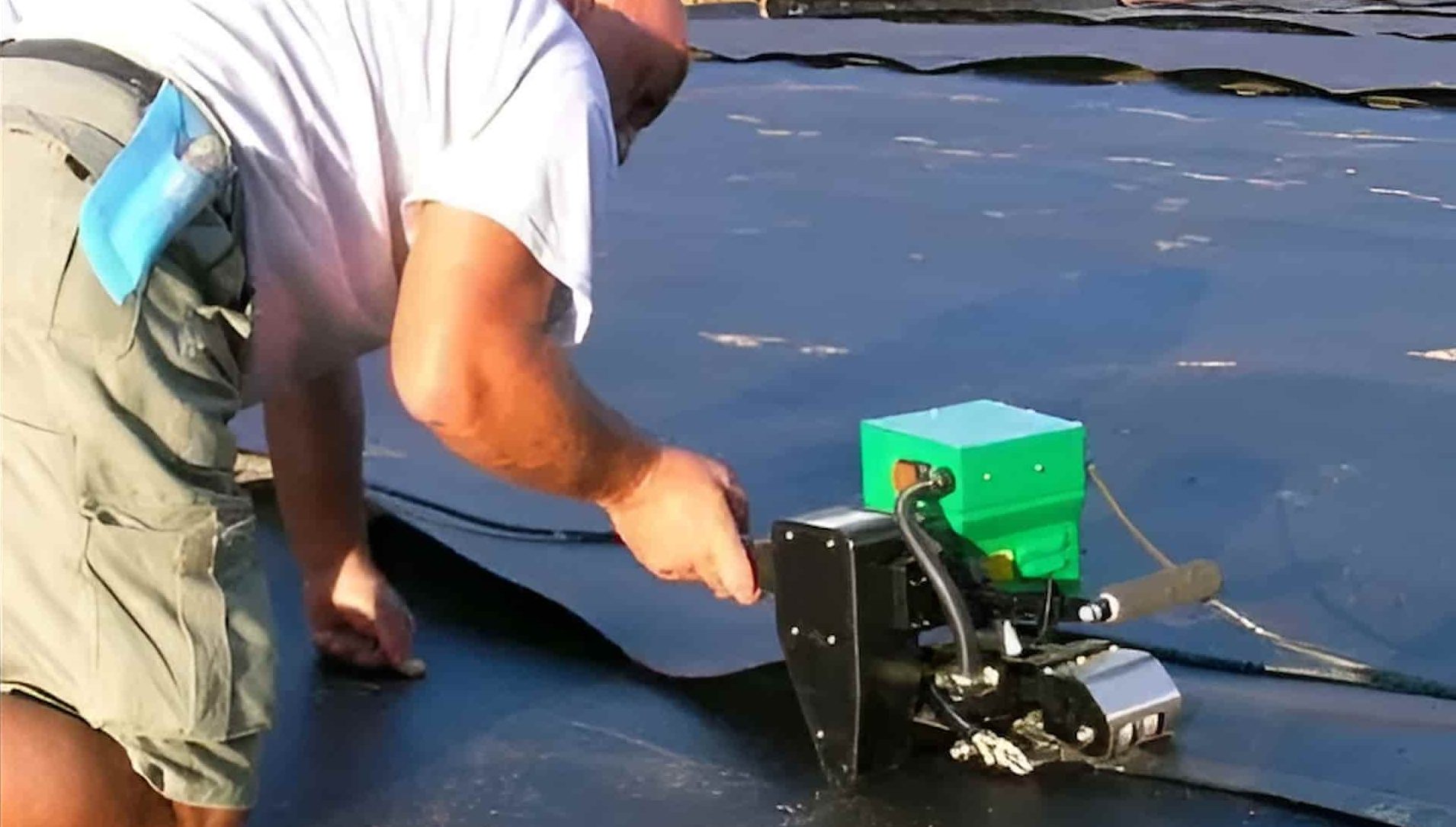

1. Dual Wedge Welding Machine – Arian Weld

The Arian Weld machine is designed by Khanjani Polymer Industries to localize the technology of thermal welding for geomembrane sheets.

It performs similarly to international models such as Leister and Ritmo and has been widely used in landfill projects, water reservoirs, tailing dams, and industrial liners.

✅ Technical Features of Arian Weld:

- Equipped with a dual wedge heating system with precise temperature and pressure control

- Two independent weld paths with an air channel between them for pressure testing

- Digital temperature and speed control with LCD display

- Capable of welding sheets from 1 to 3 mm thickness

- Operates in ambient temperatures from -5°C to +55°C

- Lightweight, ergonomic design suitable for long working hours on-site

🔍 Advantages:

Highest welding speed (up to 5 m/min)

Excellent quality control with on-site air pressure testing

Ideal for large-scale surface projects such as landfills and artificial lakes

⚠️ Operational Tips:

For best results, the geomembrane surface must be clean and dry, and operators must use proper safety equipment.

At Shahriar Baspar Arian, all operators are trained in the use of Arian Weld machines before each project to ensure optimal welding temperatures (around 350–450°C) and correct pressure adjustment.

🧰 2. Extrusion Welding Machine

The extrusion welder is used for vertical seams, corners, terminations, and reinforcement areas—locations where dual wedge welders cannot maneuver easily.

This machine melts polyethylene material and extrudes it as a hot bead into the joint, forming a very strong and durable connection.

✅ Features of Extruders Used by Shahriar Baspar Arian:

- Adjustable temperature and extrusion flow rate

- Preheating air system for surface preparation

- Uses polyethylene granules or rods of the same type as the geomembrane

- Suitable for sheet thicknesses up to 5 mm

🔍 Advantages:

- Creates highly durable welds in complex areas

- Excellent for repairing or reinforcing damaged geomembranes

- Allows precise control over bead size and weld shape

⚠️ Technical Notes:

Extrusion welding is typically performed at 220–240°C. The welding speed must match the extrusion flow rate to achieve a uniform, pore-free surface.

At Khanjani Polymer Industries, operators use both European and locally developed extruders for edge welding, pool lining, and critical repair zones.

🌡️ 3. Industrial Hot Air Gun

The industrial hot air gun (manual heat blower) is the simplest yet most versatile tool in geomembrane welding operations.

It is mainly used for localized preheating, small repairs, and quick surface adjustments.

✅ Key Features:

- Adjustable heating power (300–600°C)

- Various nozzles for focused airflow

- Lightweight and highly portable

🔍 Applications:

- Spot welding in hard-to-reach areas

- On-site seam testing and repair

- Surface preparation before extrusion or dual wedge welding

⚠️ Important Note:

Industrial hot air guns are not suitable for main or large-scale welding; they are auxiliary tools used for adjustments and finishing touches.

🧠 Key Considerations for Selecting the Right Welding Machine

- Project Type: For landfills or large ponds, Arian Weld is ideal; for corners or repairs, use the extruder.

- Geomembrane Thickness: For sheets thicker than 3 mm, extrusion welding performs better.

- Environmental Conditions: In cold climates, precise temperature control—such as in Arian Weld—is essential.

- Operator Skill: Each device requires specific training; Shahriar Baspar Arian offers free training courses for contractors and operators.

- Warranty and After-Sales Service: Arian Weld machines and Khanjani Polymer equipment include full technical support, spare parts, and on-site maintenance services.

Summary: Professional Guide to Selecting Geomembrane Welding Machines

In geomembrane projects, choosing the right welding equipment is not just a technical decision—it directly affects the final quality, service life, and overall project cost.

Using Arian Weld machines, extruders, and industrial hot air guns under the supervision of experts from Shahriar Baspar Arian and Khanjani Polymer Industries ensures international-grade welding quality and long-term durability.

With over two decades of experience in geomembrane production, installation, and testing, these two companies are ready to provide professional welding equipment and field teams for civil, agricultural, and environmental projects across the country.