Price per Square Meter of Geomembrane Sheet

Geomembranes are among the most important geosynthetics used in civil engineering, environmental, agricultural, and infrastructure projects. These polymeric sheets are widely applied for lining reservoirs, canals, dams, wastewater ponds, swimming pools, and landfills. One of the key factors affecting the total project cost is the price per square meter of geomembrane sheet.

In this article, we first discuss the main factors influencing geomembrane prices, then review the typical price ranges in Iran, and finally introduce one of the essential tools in installation — the geomembrane welding machine “ArinWeld” — explaining its impact on quality and overall project cost.

Factors Affecting the Price per Square Meter of Geomembrane

The price per square meter of a geomembrane sheet is not limited to its thickness or polymer type; several factors play a role:

- Sheet Thickness: Common thicknesses include 0.75 mm, 1.0 mm, 1.5 mm, 2.0 mm, and higher. Thicker sheets naturally cost more due to increased polymer consumption.

- Type of Polymer Used: The most common type is high-density polyethylene (HDPE) geomembrane. Other types such as LLDPE, PVC, and EPDM are also available. For instance, PVC and EPDM sheets are usually more expensive due to higher flexibility and special properties. (As referenced by NabZist, prices range between 700,000 and 2,500,000 IRR per m².)

- Roll Width and Length: The roll width (e.g., 2 m, 5 m, 7 m, etc.) and length affect production, transportation, and installation costs. Wider rolls reduce seams and joints, allowing faster installation.

- Quality of Additives: Additives such as carbon black (for UV resistance), stabilizers, pigments, coatings, or multilayer structures can increase costs. Low-quality additives may reduce durability.

- Production and Transportation Costs: Raw materials, energy, labor, and logistics — including handling and customs — all impact the final price.

- Installation and Welding Costs: Installation is a major part of total cost. The number of seams, welding method (hot wedge, extrusion, hot air), and welding quality all matter. Using the right welding machine and skilled technicians reduces costs and improves performance.

- Order Volume and Market Conditions: Bulk orders often get discounts. Exchange rate fluctuations, petrochemical prices, and global market trends also affect price changes.

Typical Price Ranges in Iran

Based on available data from the Iranian market, the approximate price per square meter of geomembrane can be estimated, though it varies by region, brand, and thickness.

- According to PipeIran, the minimum price per m² is about USD 0.30 and the maximum around USD 4.00.

- In older listings (2018), HDPE geomembranes with 1.5 mm thickness were priced between 85,000 and 130,000 IRR per m².

- Newer data (2025) suggest a range between 700,000 and 2,500,000 IRR per m², depending on type and thickness.

In general, for standard HDPE geomembranes of around 1.5 mm thickness, the price in Iran typically ranges between 100,000 and 1,500,000 IRR per m². Thicker or imported sheets may cost more.

Some suppliers list 2.0 mm geomembranes around 2,250,000 IRR per m².

Remember, the sheet price alone is only part of the total cost — installation, welding, subgrade preparation, and logistics also contribute significantly.

Importance of Installation Quality and the Role of Welding Machines

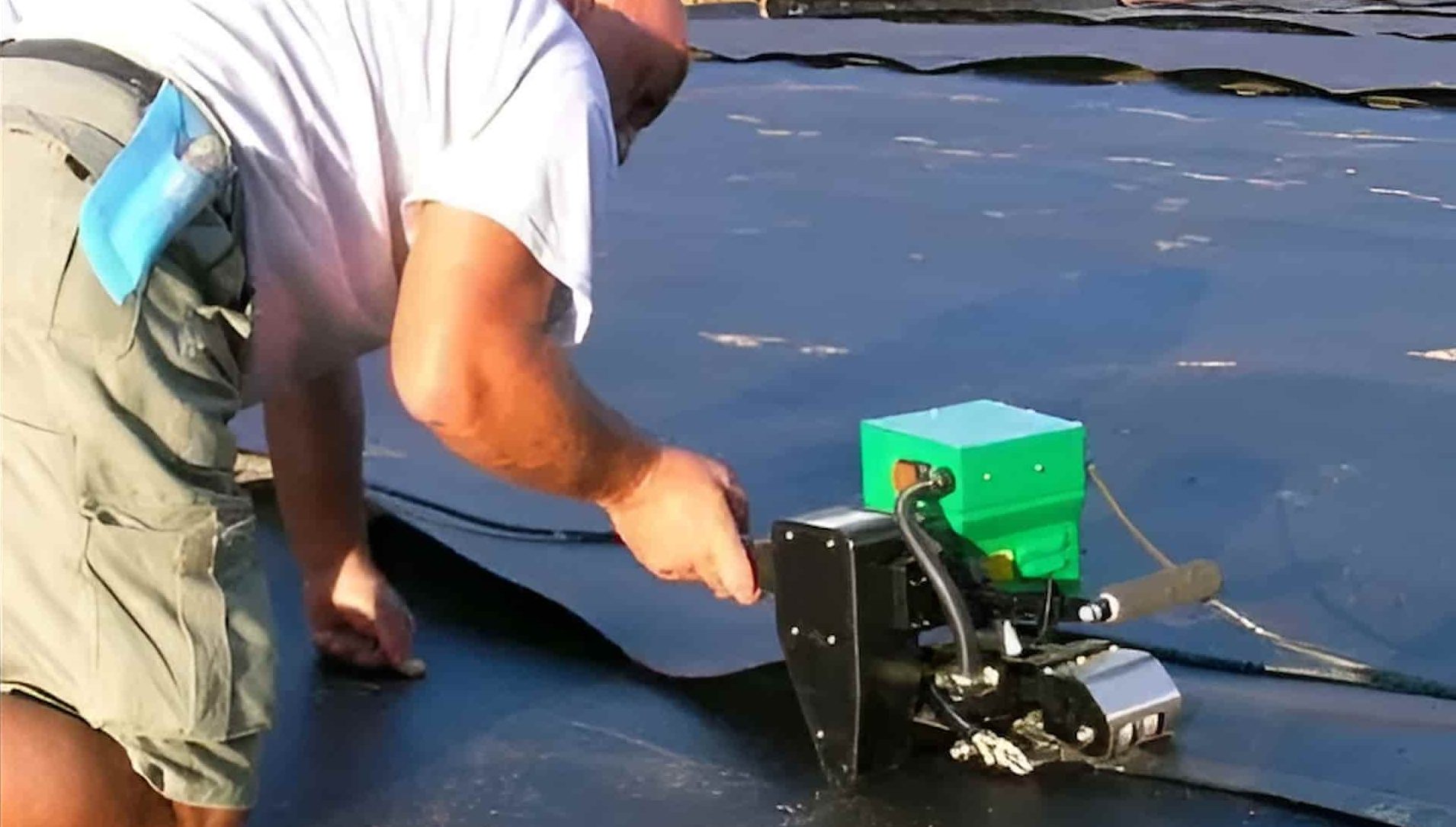

A high-quality geomembrane is only effective when installed properly. Welding precision and seam integrity are crucial. Here we review the “ArinWeld” geomembrane welding machine — one of the commercial options available in Iran.

Introducing the ArinWeld Welding Machine

The “ArinWeld” welding machine, produced by GeoKhanjani Company, is designed for thermal welding of geomembrane sheets.

Key specifications include:

- Compatible Polymer Type: Nonpolar thermoplastics (HDPE, LLDPE, etc.)

- Melting capability above 140°C (operates up to ~200°C)

- Listed Price: around 110,000,000 IRR (as per one source)

- Applications: Welding geomembranes in civil works, dams, tunnels, reservoirs, landfills, and more.

How Welding Equipment Affects Quality and Project Cost

- Improved Seam Quality: Accurate temperature, pressure, and time control ensures leak-proof seams. Machines like ArinWeld enhance seam performance and reliability.

- Reduced Maintenance Costs: Poor seams lead to leaks and damage. Investing in a reliable welding machine reduces long-term repair and failure costs.

- Lower Total Project Cost: Faster, efficient welding reduces installation time, labor, and overall project delays — directly lowering cost per square meter.

- Longer Service Life: Properly welded geomembranes last longer, providing better value over time.

Tips for Choosing a Welding Machine

- Ensure sufficient temperature range (≥140°C)

- Accurate control of temperature, pressure, and speed

- Reliable after-sales service and spare parts availability

- Proven performance and field experience

- Balance initial machine cost vs. long-term project savings

Integrating Sheet Price and Welding Quality

When evaluating geomembrane costs, don’t just consider the sheet price. Even an affordable sheet can lead to high repair costs if poorly installed. Consider:

- Sheet quality assurance and standards (e.g., GM13 certification)

- Installation, subgrade preparation, and surface leveling

- Seam quantity and welding method

- Welding machine performance and crew skill

- Warranty and after-sales service

- Potential future maintenance or repair costs

Summary: Geomembrane Sheet Price per Square Meter

The price per square meter of geomembrane depends on many variables — thickness, polymer type, roll width, additive quality, installation, and welding equipment. In Iran, prices range from a few hundred thousand to several million IRR per m².

The ArinWeld geomembrane welding machine plays a vital role in ensuring proper seam quality and long-term performance.

If you plan to implement a geomembrane project:

- Compare prices, thicknesses, and types from multiple suppliers

- Calculate installation and welding costs separately

- Use reliable welding equipment and skilled operators

- Check for standards, warranty, and technical support