The Best Geomembrane Welding Machine: “Arian Weld”

In waterproofing projects (landfills, ponds, storage tanks, green roofs, etc.), the quality and stability of geomembrane joints determine the durability of the entire structure. Choosing the right welding machine not only increases installation speed but also minimizes leakage risks and future repair costs.

This practical article for technical managers and contractors of “Shahriyar Baspar Arian” explains different types of machines, selection criteria, key parameters, maintenance guidelines, and several purchase recommendations.

Precision, Speed, and Strength in Waterproofing Projects

• Exclusively manufactured by Shahriyar Baspar Arian with warranty and after-sales service.

• Adjustable temperature and speed for various polymer sheets.

• Suitable for welding in ponds, lagoons, dams, and landfill sites.

• Ensures fully watertight and durable seams under different environmental conditions.

1. Types of Geomembrane Welding Machines — Applications and Advantages

There are generally three main families of welding machines:

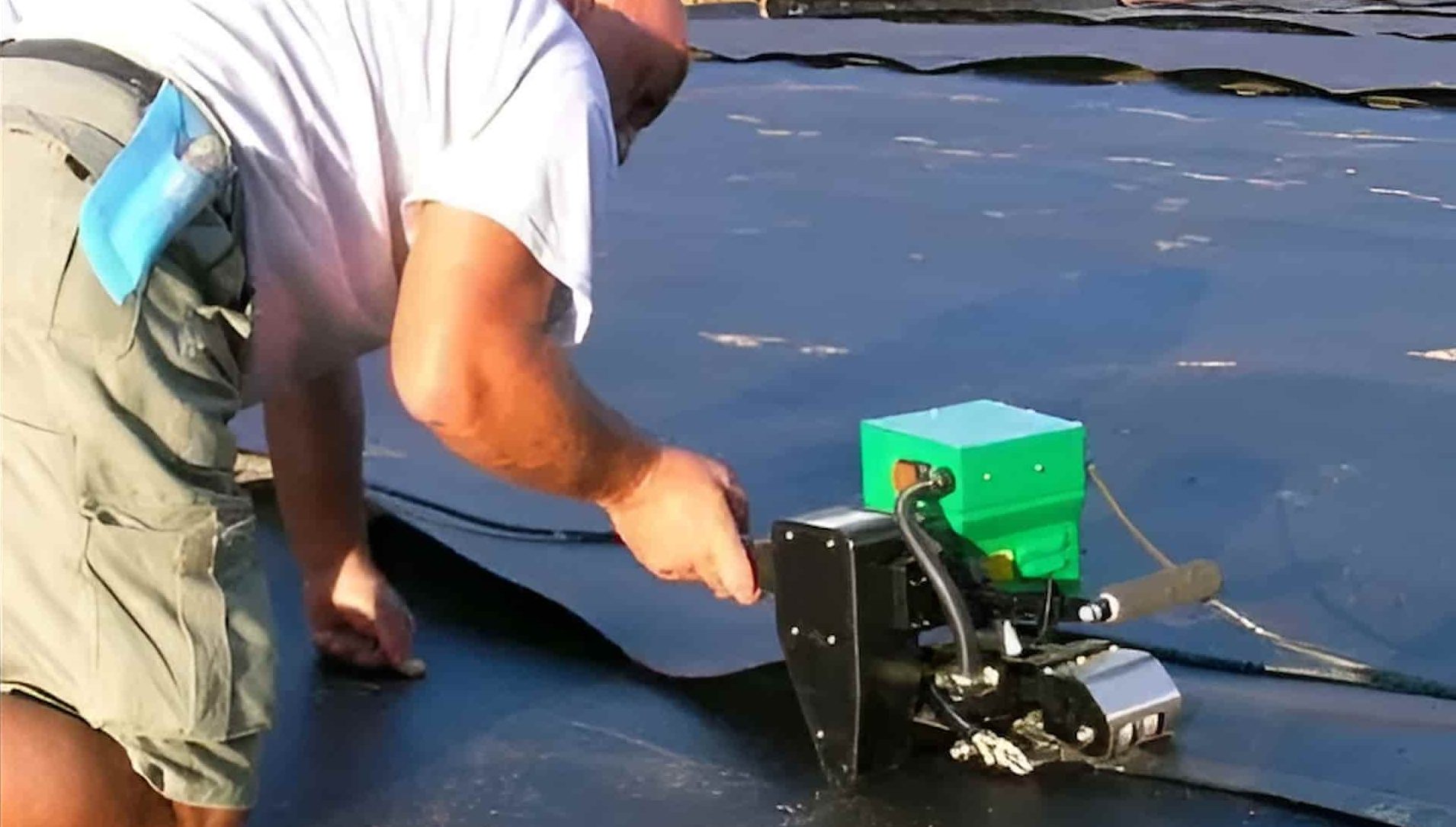

1.1. Arian Weld — Local Geomembrane Welding Machine

Introduction and Market Position

- “Arian Weld” is an Iranian-made geomembrane welding machine widely used among domestic geomembrane suppliers.

- This machine is supplied with warranty and after-sales support, and is claimed to be manufactured under Swiss supervision.

- Geo Khanjani Co. is one of the official distributors of this model.

1.2. Industrial Heat Gun / Hot Air Gun

Function and Application in Geomembrane Welding

An industrial heat gun is a key tool for partial welding, repair, and preheating the edges of sheets. It works by blowing hot air at adjustable temperatures onto the geomembrane surface to soften it, followed by pressure using a roller or other tool to bond the sheets.

In many projects, heat guns are used as complementary tools alongside wedge welders and extrusion welders.

Specifications

- Power: Typically 1600 W, with some heavy-duty models up to 3400 W.

- Adjustable temperature: e.g., 40–700°C for Leister Triac ST model.

- Lightweight and portable: Some models weigh less than 1 kg, ideal for small spaces or limited access areas.

Advantages

- Flexibility and repair use: Ideal for patching, sealing corners, and small or hard-to-reach seams.

- Low cost and easy maintenance: Compact, affordable, and simple to maintain.

- Localized temperature control: Allows precise heat application without affecting the surrounding area.

Limitations

- Slower speed: Compared to wedge or extrusion welders.

- Limited sheet thickness: Less effective for thicker geomembranes where deep heat penetration is needed.

- Operator skill required: Correct temperature, angle, and movement control are essential to avoid overheating or poor bonding.

1.3. Extrusion Welder

An extrusion welder works by melting a compatible polymer rod or granule and extruding it into the joint between sheets. After cooling, it creates a strong, filled seam. This process is similar to small-scale plastic injection welding.

Applications

- Repairing damaged areas: Used to refill and restore broken seams.

- Reinforcing seams: Adds filler material to enhance strength and reduce voids.

- Vertical or complex joints: Effective where wedge welders are difficult to use.

Advantages

- Strong reinforced welds: Filler material increases strength and reduces porosity.

- Ideal for local repairs: Targeted application on critical joints.

- Nozzle flexibility: Different nozzles can control seam width and flow rate.

Limitations

- Material compatibility required: Filler and sheet must match chemically for proper bonding.

- Limited speed on long seams: Slower compared to automatic wedge welders.

- Temperature control needed: Preheating and environmental control improve bonding quality.

2. Key Technical Parameters to Check

Before purchasing, compare the following:

- Weldable thickness and material type — e.g., up to 2.5–3.0 mm; compatible with HDPE, LDPE, PVC, EVA, etc.

- Temperature control accuracy — precise digital adjustment within 420–450 °C range.

- Welding speed (m/min): Portable models: 0.8–3.5 m/min; automatic types are faster.

- Pressure and seam width: Typically dual 15 mm seams with adjustable pressure for good fusion.

- Power and voltage: 220 V/380 V compatibility and energy efficiency for field conditions.

- Automation: For large projects, self-propelled wedge welders with data recording are ideal.

3. Quality Assurance and Testing

- Test welds: Perform peel and shear tests, visual checks, and non-destructive air/water pressure tests.

- Parameter recording: Log temperature, speed, and pressure data for warranty or QA documentation.

- Environmental control: Protect welding areas from moisture, cold, or strong winds using covers or heaters.

4. Operator Training and Maintenance

- Operator training: Skill in adjusting temperature, speed, and pressure defines weld quality.

- Daily maintenance: Clean wedges/nozzles, check cables, and calibrate thermostats regularly.

- Spare parts and support: Ensure access to wedges, heaters, nozzles, and sensors locally through reliable suppliers such as Khanjani Polymer Industries.

5. Purchase Tips for “Shahriyar Baspar Arian”

- Define project needs: Large projects (landfills, tanks) benefit from self-propelled wedge welders; small repairs require portable models.

- Balance price and quality: Compare practical parameters — temperature control, element durability, and service availability — rather than just price.

- Warranty and local service: Choose suppliers with service centers in Iran to minimize downtime.

- Compliance with standards: Ensure welding processes meet international quality and testing standards.

6. Recommended Starter Package

For a contractor like “Shahriyar Baspar Arian,” a balanced setup includes:

- One self-propelled digital wedge welder for long seams.

- One portable extrusion welder for reinforcement and critical repairs.

- One compact hot air gun for detailed or corner works.

This combination ensures optimal speed, quality, and cost efficiency for diverse project needs.

Conclusion and Consultation Offer

The “best” geomembrane welding machine depends on project conditions, sheet type, and technical support.

For large HDPE works, wedge and extrusion welders are most efficient, while hot-air welders suit detailed or repair tasks.

It is recommended that the technical team of Shahriyar Baspar Arian select and test three models based on these parameters before final purchase.

For customized supplier lists, model comparisons, and technical catalog preparation, you can share project details (sheet type, thickness, annual workload) to receive a tailored recommendation and budget estimate.