Double Wedge Sheet Welding Machine: A Precise and Efficient Solution for Joining Geosynthetic Sheets

The geosynthetics industry is rapidly expanding, with growing applications in civil engineering, environmental projects, road construction, and waste management. One of the most critical stages in geosynthetics installation is the sheet welding process, which ensures the creation of large, seamless liners. Among various available methods, the Double Wedge Welding Machine is increasingly recognized as a reliable, fast, and highly accurate solution for large-scale and sensitive projects. Arian Welding – Shahriar Baspar Arian, with extensive experience in supplying and implementing industrial machinery and geosynthetic welding equipment, plays a key role in improving the quality of engineering projects.

What Is a Double Wedge Welding Machine?

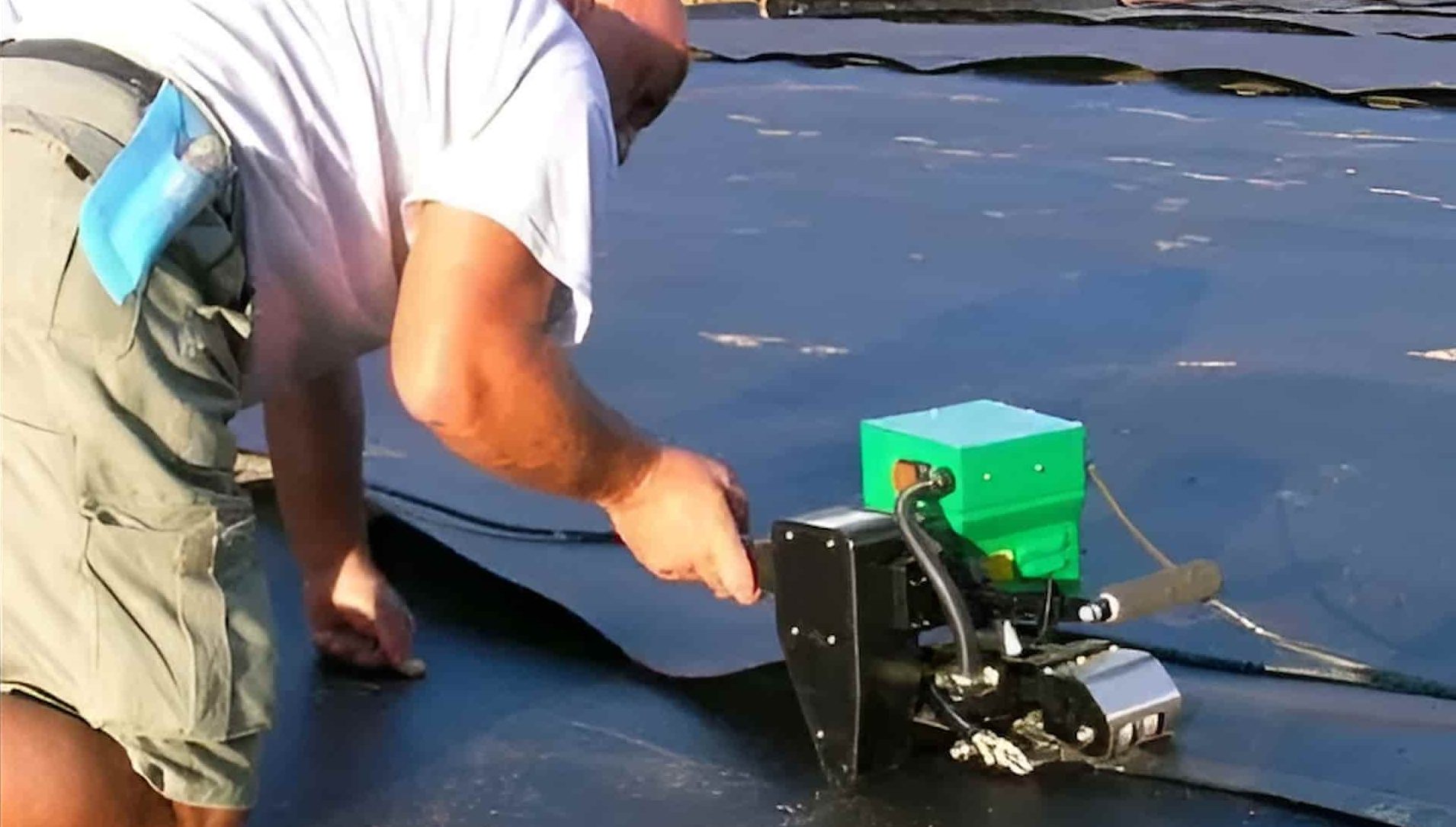

A double wedge welding machine is a thermal mechanized device designed for joining polyethylene (PE), polypropylene (PP), and other geosynthetic sheets. By applying controlled heat and simultaneous pressure, the machine melts and fuses two sheet edges into a continuous, homogeneous seam. The term “double wedge” refers to the presence of two wedge-shaped heating elements that symmetrically and uniformly apply heat and pressure to the sheets.

These machines are available in portable, semi-automatic, and fully automatic models, selected based on project requirements and sheet specifications.

Why Is Sheet Welding Important?

In projects such as water reservoirs, landfill liners, drainage systems, and liquid transfer channels, geosynthetic sheets are typically installed in large panels rather than single-piece liners. Improper or non-standard welding can lead to:

- Leakage of liquids or gases

- Structural weakness of the lining system

- Reduced service life of the project

- Increased maintenance and repair costs

Therefore, using equipment with precise control over temperature, pressure, and welding speed is essential.

Advantages of Double Wedge Welding Machines

1. Uniform and Defect-Free Welds

Thanks to the dual wedge design, heat is evenly and consistently transferred to the sheet edges. This results in a strong, homogeneous molecular bond compared to manual methods or other technologies that may apply uneven heat or pressure.

2. Increased Installation Speed

Due to automated operation and precise control, double wedge machines perform welds significantly faster than traditional methods. This advantage is especially critical in large-scale projects, where execution time directly affects overall project costs and commissioning schedules.

3. Precise Parameter Adjustment

Modern machines allow accurate adjustment of temperature, pressure, travel speed, and heating time. These parameters can be optimized according to sheet type, thickness, and environmental conditions, ensuring consistent mechanical strength and weld quality.

4. Reduced Human Error

Manual welding requires high operator skill, and even experienced technicians may make errors under challenging site conditions. Double wedge machines rely on automated controls, significantly reducing the risk of human error.

5. User-Friendly Operation

Despite their advanced internal design, these machines are easy to operate and train on. Many models feature digital displays, touch controls, and error alarm systems that simplify operation for field personnel.

Key Technical Features of a Standard Double Wedge Welding Machine

To ensure optimal performance, a sheet welding machine should include the following technical features:

- Digital temperature control for precise heat adjustment

- Symmetrical wedge system for uniform heat and pressure distribution

- Adjustable pressure profile to match material type and sheet thickness

- LCD or LED display for real-time parameter monitoring

- Communication ports for process monitoring, data logging, or computer connection

- Durable yet lightweight structure for easy transportation on-site

Arian Welding – Shahriar Baspar Arian: A Pioneer in Welding Equipment Supply and Services

Arian Welding, a subsidiary of Shahriar Baspar Arian Group, has earned a strong reputation in Iran and the region through years of experience in supplying, selling, and providing after-sales services for industrial geosynthetic welding equipment, including double wedge welding machines.

Why Choose Arian Welding?

1. Wide Product Range

Arian Welding offers a variety of welding machines with diverse technical specifications, suitable for projects ranging from small-scale applications to national infrastructure developments.

2. Strong Technical Support

The company provides consulting and technical support before purchase, during installation, and after sales, ensuring clients select the most suitable equipment for their specific project needs.

3. Training and Execution Services

Arian Welding conducts training programs for operators and technicians, ensuring proper and high-quality use of the equipment in real project conditions.

4. Spare Parts Supply and After-Sales Service

Reliable spare parts availability and periodic maintenance services protect customers’ long-term investments and ensure consistent machine performance even under demanding working conditions.

Practical Applications of Double Wedge Welding Machines

Landfill Lining Systems

In municipal waste landfills, high-thickness polyethylene geomembranes are essential to prevent leakage. Double wedge welding machines provide strong, reliable seams that meet strict environmental standards.

Reservoirs and Ponds

For water or chemical storage reservoirs, geosynthetic sheets must be fully watertight. Proper welding prevents leakage and protects surrounding soil and groundwater.

Canal and Drainage Linings

In drainage and canal lining projects, uniform and secure welding using double wedge machines significantly improves system efficiency and service life.

Conclusion

The double wedge welding machine is one of the most critical tools in the geosynthetics industry, delivering strong, uniform, and reliable geomembrane sheet welds that are essential for modern engineering projects. Arian Welding – Shahriar Baspar Arian, with its diverse product portfolio, comprehensive technical support, and specialized training services, is a trusted partner for supplying this equipment across various projects.

These machines not only enhance installation quality but also optimize time and costs by reducing human error and increasing execution speed. Choosing the right equipment and collaborating with experienced suppliers like Arian Welding can be the key to the success of large-scale and sensitive engineering projects.