Introduction to Geomembranes and Their Applications in Environmental Protection Systems

Explanation of different types of geomembranes (HDPE, PVC, etc.) and their applications in environmental engineering, including landfill systems, insulation, and water dams.

Introduction and Importance of Using Geomembranes in Civil and Environmental Projects

In recent decades, with the rapid growth of civil and infrastructure projects, the need to control water seepage, prevent soil contamination, and protect environmental resources has become increasingly critical. Among modern materials, geomembranes—as a key member of the geosynthetics family—play an essential role in environmental, geotechnical, and hydraulic engineering. Due to their unique properties such as high impermeability, long service life, and chemical resistance, geomembranes have become an excellent substitute for traditional sealing methods such as concrete, bitumen, or compacted clay.

What Is a Geomembrane?

A geomembrane is an impermeable polymeric sheet typically made of high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC). These sheets are produced in large rolls with varying thicknesses (usually between 0.5 and 3 mm) and are welded together on-site using specialized welding machines to form a completely sealed and continuous barrier.

Among the various types, HDPE geomembranes are the most widely used due to their high mechanical strength, UV resistance, and cost efficiency in both civil and environmental applications.

Technical Features and Advantages of Geomembranes

- Excellent impermeability: The permeability coefficient of geomembranes is about 10⁻¹⁴ m/s, which is practically considered zero—making them ideal for preventing leakage of water or chemicals.

- Chemical and biological resistance: Geomembranes are resistant to acids, alkalis, salts, and microorganisms, which makes them suitable for industrial and landfill environments.

- Long service life: When properly installed, high-quality geomembranes can last over 50 years.

- Ease and speed of installation: Installation is significantly faster than traditional methods, and the use of professional welding equipment ensures fully sealed, uniform seams.

- Cost efficiency: Compared to concrete or compacted clay liners, geomembrane systems are more economical and require less maintenance.

Main Applications of Geomembranes

1. Construction of Water Reservoirs and Agricultural Ponds

In irrigation and agricultural projects, HDPE geomembranes are used for lining ponds and canals to significantly reduce seepage and evaporation losses, especially in arid regions of Iran.

2. Urban and Industrial Landfills

One of the most critical applications of geomembranes is in the lining of landfill bases and walls, preventing leachate contamination of groundwater and surrounding soils.

3. Wastewater Treatment Plants and Industrial Tanks

In chemical and petrochemical industries, geomembranes are used to line tanks and containment areas for acidic, basic, or fuel materials.

4. Mining and Dam Engineering

In mining, geomembranes are applied in leach pads to prevent contamination caused by chemical solutions. They are also used in earth dams to enhance water tightness in the core or face zones.

5. Canal and Tunnel Linings

Using geomembranes in tunnel and canal linings prevents seepage and erosion, significantly increasing the lifespan of the structure.

6. Environmental and Groundwater Protection Projects

Geomembranes play a vital role in wastewater storage, evaporation ponds, and stormwater collection basins, protecting groundwater from contamination.

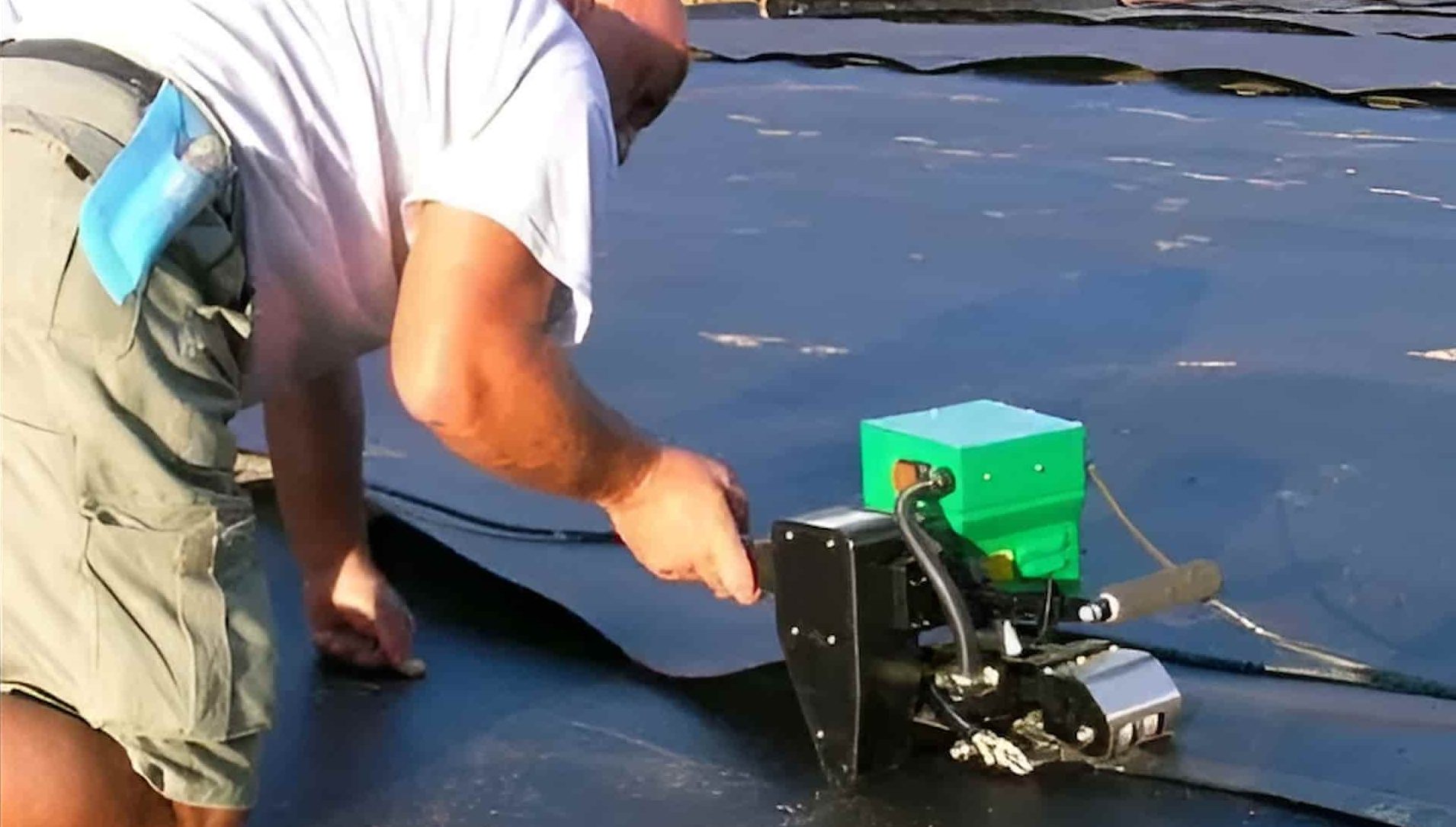

Importance of Welding Machines in Geomembrane Installation

To ensure complete impermeability, geomembrane sheets must be welded with high precision using specialized welding machines.

Shahriar Bespar Aryan Company, leveraging advanced technical expertise and years of experience, is recognized as the largest manufacturer and supplier of automatic geomembrane welding machines, manual extruders, and industrial hot air guns in Iran and the Middle East.

The company’s welding equipment is capable of joining HDPE, LLDPE, PVC, and TPO sheets with precise control of temperature and pressure. Accurate regulation of welding speed, temperature, and roller pressure ensures uniform, leak-free seams.

Types of Geomembrane Welding Machines by Shahriar Bespar Aryan:

- Automatic dual-track welding machines for long seam welding over large surfaces

- Manual extruders for repair work and specific joint areas

- Industrial hot air guns for drying and preheating before welding

All equipment manufactured by this company meets international ASTM and GRI-GM13 standards and has been successfully used in numerous national projects.

Quality Control and Testing

Quality assurance during installation is crucial, as even a minor welding defect can compromise the entire system’s performance. After installation, the following tests must be carried out:

- Air Pressure Test for dual-track seams

- Spark Test for extrusion welds and repairs

- Tensile and Shear Test of welded samples in the laboratory

Shahriar Bespar Aryan not only supplies equipment but also provides technical services such as operator training, site inspection, and engineering consultancy to ensure optimal project performance.

Advantages of Partnering with Shahriyar Baspar Arian

✅ The largest manufacturer and supplier of geomembrane welding machines, extruders, and industrial hot air guns in Iran and the Middle East

✅ High-quality geomembrane sheets meeting international standards

✅ After-sales support, operator training, and full technical assistance

✅ Proven experience in national-scale projects, including dams, wastewater plants, landfills, and agricultural reservoirs

Summary: Introduction to Geomembranes and Their Applications

Geomembranes, as modern engineering materials, have revolutionized sealing systems and environmental protection methods. Their use in civil and industrial projects improves durability, reduces costs, and prevents environmental pollution.

Shahriyar Baspar Arian, as the leading manufacturer and supplier of geomembrane welding equipment in Iran and the Middle East, designs and produces a full range of automatic welding machines, manual extruders, and industrial hot air guns.

The company is not only a top supplier but also a trusted technical partner for contractors and clients in major national projects.

By using Shahriar Bespar Aryan’s products and services, every geomembrane project can be executed with maximum quality, precision, and long-term reliability.